When working with ICS, the first benefit is going to be to your bottom line.

When working with ICS, the first benefit is going to be to your bottom line.

Benefits of Choosing ICS Wear Group, Growing National and International demand improves shipping processes and reduces costs! In an effort to save costs and with a growing demand for our products worldwide, we have set up over 80 accounts with various local, international & government agencies to ensure that your products are shipped cost effectively while arriving on time and intact.

Our logistics team is updated and well-educated on all country standards relating to crating, customs documentation and transport times.

ICS is a cost-effective operation allowing us to pass our cost savings on to you, the customer. For example, although raw iron prices have soared over 65 percent recently, ICS has been able to hold its overall cost increases to five percent annually. When you compare the prices of our parts, you will notice significant savings over OEM provided parts.

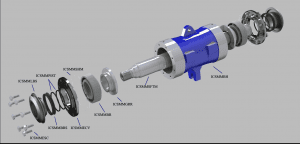

We manufacture and cast superior components that last longer and require less maintenance as well as providing alternate options which maximize your investment in your original equipment.

We manufacture and cast superior components that last longer and require less maintenance as well as providing alternate options which maximize your investment in your original equipment.