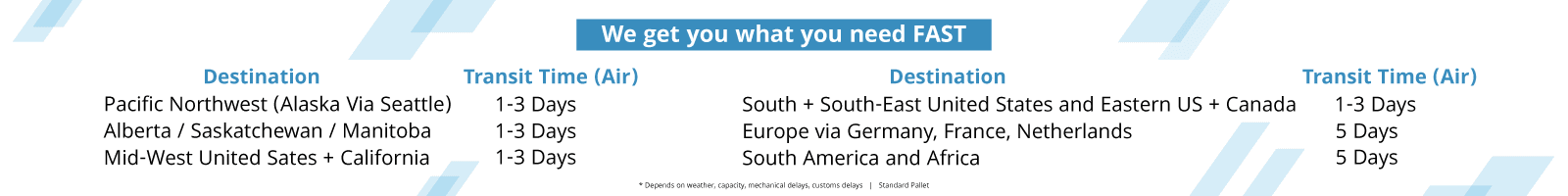

Fast worldwide shipping

Up to 30-40% less expensive than the competition

Up to 25% more efficient pumps than the competition

We can replace Warman®, Metso®, Millmax®, and GIW® pumps or pump components

Backed by our leading guarantee

Made in Canada. Custom orders & ready to ship pumps & parts available

Exceptional customer service

Keep your pumps online and your site running with ICS Wear Group

Slurry pumping is the life blood of any mining site. It’s critical that your pumping equipment is capable of handling the most extreme conditions.

100% compatible with Warman®, Metso®, and Goulds® pumps

Our pump parts aren’t only compatible with our ICS Mill Master line of heavy duty slurry pumps. They’re also 100% compatible with any OEM components you may have on site.

If you’re having problems with your existing pump or need a brand new one, we can help. Is your existing pump vibrating a lot or leaking? Does your slurry pump shaft break frequently? Are you having problems with wear life of your pump? Whatever your issue, our industry-leading slurry pumps and our experts can help.

Expand for more information

Heavy Duty Wet Ends are the wearable parts within a Pump. That consist:

- Volute

- Frame Plate Liner Insert

- Rubber Cover and Frame Plate Liners

- Impellers

- Throatbush

ICS Heavy Duty parts are 100% interchangeable.

Impellers and Throatbushes are available in all sizes. Parts can be ordered in either High Chrome or Rubber depending on your pump set up.

ICS Replacement Kits

Available kits contain everything you need to change out your wet end parts including O-Rings and Seals.

Bearing Assemblies (BAU) are a component of the complete pump. The BAU is an important part of slurry pump and the most important part of drive power unit. Used to connect the Pump to the Motor, operation of the BAU will directly affect the service life of the pump.

Wet End parts of the BAU consist of: Laby Seal, Bearing Seal, Piston Rings, End Cover, Shims, Bearing, Grease Retainer.

Drive end parts of the BAU consist of: Grease Retainer, Bearing, Shims, End Cover, Piston Rings, Bearing Seals, Laby Seal.

These parts sit on the shaft and are protected by the bearing housing. See the drawing below for a basic bearing outline.

ICS also offers a complete line of Bearing Assembly Rebuild Kits, consisting of all the internal parts required to rebuild your Bearing Assembly, these kids come in a variety of materials and sizes, Contact us today for a quote

All ICS Wear Group BAU’S are manufactured using only western bearings and stainless steel end covers and shipped in locally made custom crates to prevent against environmental and shipping hazards.

ICS Bearing Assemblies come in all sizes from 1.5×1 to 20×18.

Mechanical seal arrangements, stuffing boxes and expellers in stainless steel and high chrome white iron, ranging from 28% to 38% HCWI. Our standard is 28% one percent above the normal. Our expeller rings can also be produced in rubber.

Stuffing Box Seal Arrangements include: seal ring, stuffing box, shaft spacer, lantern restrictor, shaft sleeve, packing and gland seal.

Stuffing Box arrangements come in all sizes from 1×1 to 20×18.

Expeller Seal Arrangements include: seal ring, expeller, expeller ring, shaft sleeve, neck ring, packing, lantern ring, and gland seal.

Expeller Seal arrangements come in all sizes from 1×1 to 20×18.

Mechanical Seal Kit for 1.5×1 pump includes: sleeve, mechanical seal, mechanical seal adaptor and frame plate liner insert.

ICS Mill Master sleeves overlay maintains the correct combination of properties that allow for exceptional performance. The combination of high hardness, high density, high bond strength, non-galling, low friction and exceptional corrosion resistance allows ICS HP wear sleeves to outperform many exotic “high performance” coatings in the most demanding, abrasive pumping applications.

A packing application applies specific demands on the equipment, specifically friction and abrasion. While tungsten carbide and other exotic overlays provide an exceptionally hard wear surface, carbides are held in place by relatively soft binding alloys. Binders erode, exposing carbides that further complicate the wear situation when forced to run at high surface speeds against relatively soft packing polymers. This is a perfect example where increased hardness is not directly related to increased wear life.

Benefits of ICS Shaft Sleeves

- Smooth sliding surface, resists scouring, while preventing packing from being damaged

- Fewer sleeve change-outs, saving money

- Significant improvement in running time, saving money

ICS Pump Covers are designed to be strong and powerful, manufactured in materials ranging from Mild Steel to Stainless Steel to Aluminum. These pump covers are designed to fit the ICS High Performance line of pumps, as well as the “AH” Series of pumps, ranging in size from 1.5×1 up to and including 20×18. Our pump covers meet the safety standards and operational requirements outlined for slurry pumps worldwide.

Each custom pump cover consists of a vertical seam and user-friendly fastening system that allows for quick, safe, and efficient installation while maximizing uptime and eliminating unnecessary downtimes.

The manner to which these pump covers are manufactured ensures that all standard maintenance and performance inspections can be achieved.

Benefits of ICS Pump Covers

- Operator safety

- Cost effective

- Ease of maintenance

- Quick and efficient mounting and removal

- Continuous vibration analysis point access once cover is installed

- Ease of viewing

- Custom hardware

ICS manufactures discharge joint rings, intake joint rings, o-rings and seals for the mining and other commercial industries.

Materials used include: EPDM rubber (e.g. epdm rubber seal), commercial Nitrile (e.g. Nitrile o rings), Butyl, Hypalon, Neoprene and Viton (e.g. Viton o rings).

Our Discharge Joint rings (DJR) is a component within the wet end assembly used to seal the outlet of a metal lined pump while our Intake Joint Rings (INJR) is also a component within the wet end assembly that is sued to seal the inlet of a metal lined pump. Both our Discharge Joint Rings and Intake Joint Rings are 100% compatible with Warman®, Metso®, and Goulds® pumps and are available from 1.5×1 to 16×14 to 450 stlr. In addition to the AH we also can supply your submersible, high head and gravel pumps.

ICS Impeller O-Rings (IOR) and Shaft O-Rings (SOR) are created from the highest quality rubber to meet the demands of the job. ICS O-rings range from 1.5×1 to 16×14 to 450 stlr. We can also make custom O-Rings based on individual needs.

ICS seals include Seal Rings (SLR), Volute Liner Seals (VLS), Lip Seals (LIP), and Bearing Seals (BRS). All our seals are tested to the highest of qualities to meet the extreme needs of our customers. ICS seals come in our complete line of sizes and kept in stock in our warehouse.

Slurry Pumps and Parts for Every Application

Depending on your current application, ICS Wear Group can supply all motor mounts, guards, and motors to ensure that you are pumping at the best efficiency point. Our testing shows ICS Heavy Duty Mill Master pumps operate between 11-25% more efficient than the competition, including Warman®, Metso®, Millmax®, and GIW®.

- Mineral Processing

- Underground Mining

- Surface Mining

- Mill Thickener

- Coal Prep

- Cyclone Feeds

- Aggregate Processing

- Fine Primary Mill Grinding

- Chemical Slurry Service

- Tailings

- Secondary Grinding

- Industrial Processing

- Pulp and Paper

- Food Processing

- Cracking Operations

- Ash Handling

- Petro Chemical

- Sulfuric Acid

Looking for a Quote on Slurry Pumps or Slurry Pump Parts?

Our value, service and delivery speed are unmatched.

We supply slurry pumps and slurry pump parts to clientele all over the world. Whether you need a new pump or a pump part, we’ve got you covered. Our parts also fit Warman®, Metso®, Millmax® GIW® and other OEM pumps.

Our Customers Love Us, Here’s What Some of Them Are Saying:

Complete the form below to connect with our pump experts

We have ready to ship pumps and parts in stock or we can make you a custom pump or part made to order. Submit the form below and our pump specialists will contact you to discuss your needs. Shipping Worldwide!